Zahlungsart:L/C,T/T,D/P,Paypal

Incoterm:FOB,CFR,CIF,EXW,FCA,CPT,CIP,DEQ,DDP,DDU

Minimum der Bestellmenge:100 Kilogram

Transport:Ocean,Land,Air

Hafen:Shanghai,Qingdao,Shenzhen

$1.99-9.99 /Kilogram

Modell: HP-HTB

Marke: HP

Herkunftsort: China

Specified Size: Make To Order

Verpakung: Holzkiste

Produktivität: 100 tons Month

Transport: Ocean,Land,Air

Ort Von Zukunft: China

Unterstützung über: 500 tons per year

Zertifikate : ISO9001: 2015

HS-Code: 7325101000

Hafen: Shanghai,Qingdao,Shenzhen

Zahlungsart: L/C,T/T,D/P,Paypal

Incoterm: FOB,CFR,CIF,EXW,FCA,CPT,CIP,DEQ,DDP,DDU

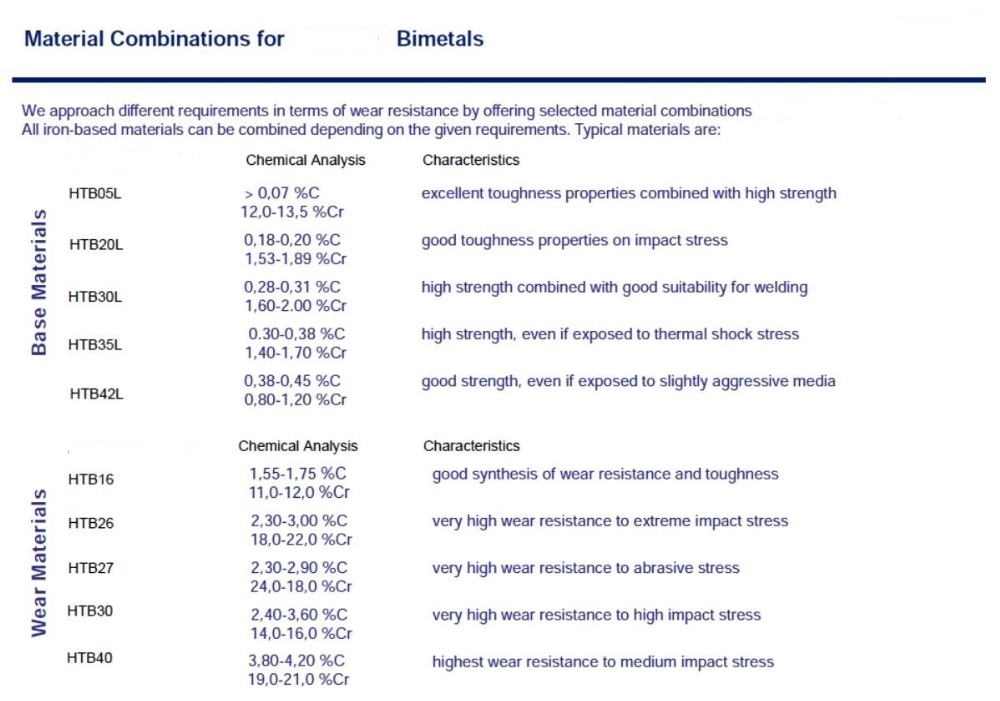

HP Wear Resistant Group offers the various Bi-Metal Casting Materials like Casting Wear Liners for the customers who need to solve wear problem like cement plant, steel mill, mining site, etc... The challenging environments inherent in cement production dictate durable long lasting parts are used within the mills. Our experienced engineering and sales departments understand the requirement of supplying to our cement customers high quality parts that are long lasting and reduce downtime.

Besides serving to cement plant, we supply customers a broad range of Casting Wear Parts including Hammer, Wear Point, Fan Blades, Dredge Teeth & Adapter, Crusher Teeth, etc... Come to find out us and we will assistant you with Casting Wear Teile.

Standard Specifications of HP Casting Materials :

Packing & Delivery

Packing Way: By Wood Case, By Steel Pallet

Delivery Time: 30 days after order confirmation

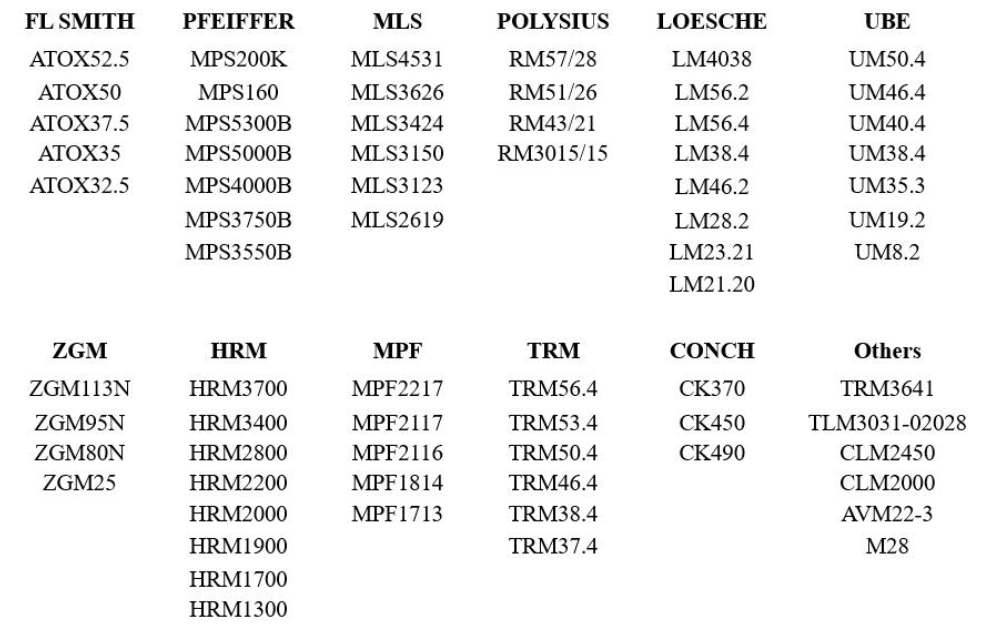

The Brand of Vertical Mill we serve

Firmeninformation

HP Plate (Huifeng Wear Resistant Industry Co., Ltd.) was founded in 1994, as the former Taiwan's Upking-Kurimoto Ltd., led by president Mr. Zhang Kun-Mou, using the world-famous Japanese KURIMOTO hardfacing welding patented technology & welding materials produced by Vautid GmbH. HP Plate has become the most experienced expert providing one-stop wear solution.

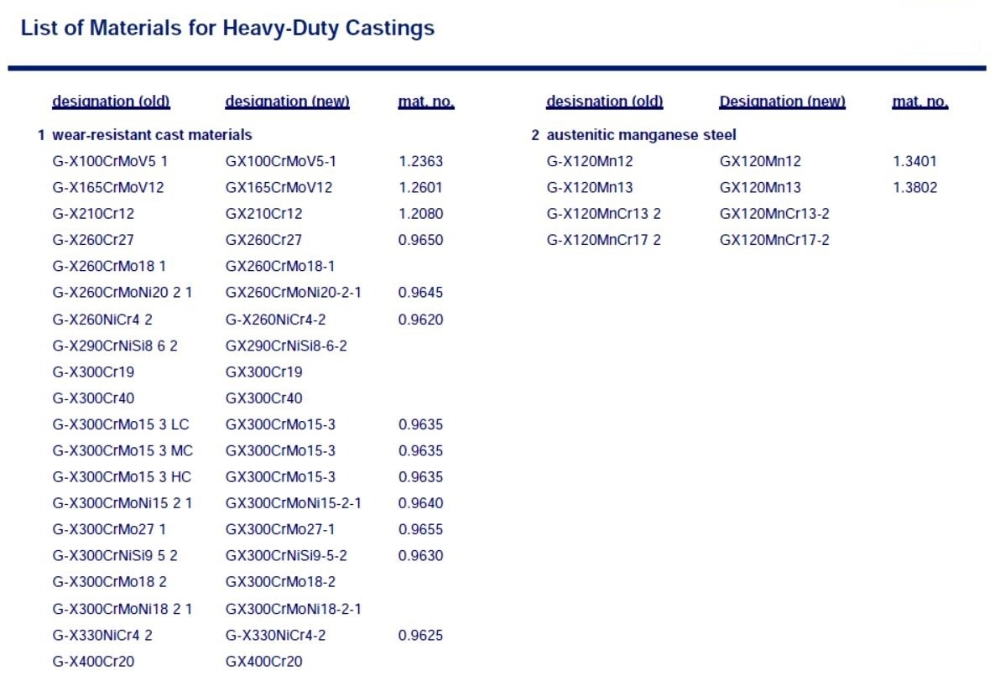

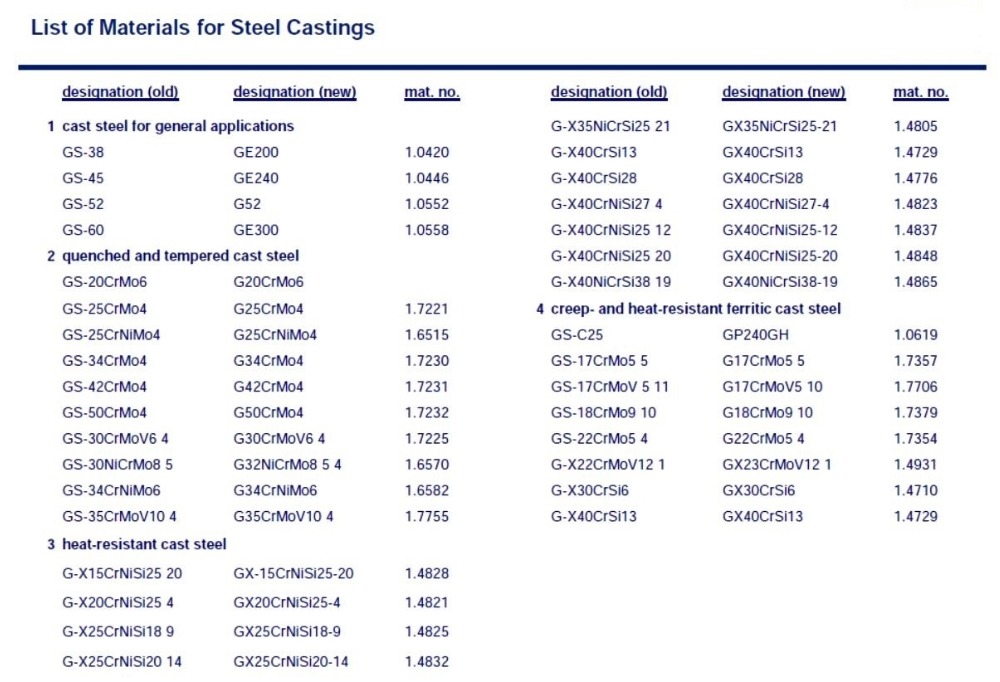

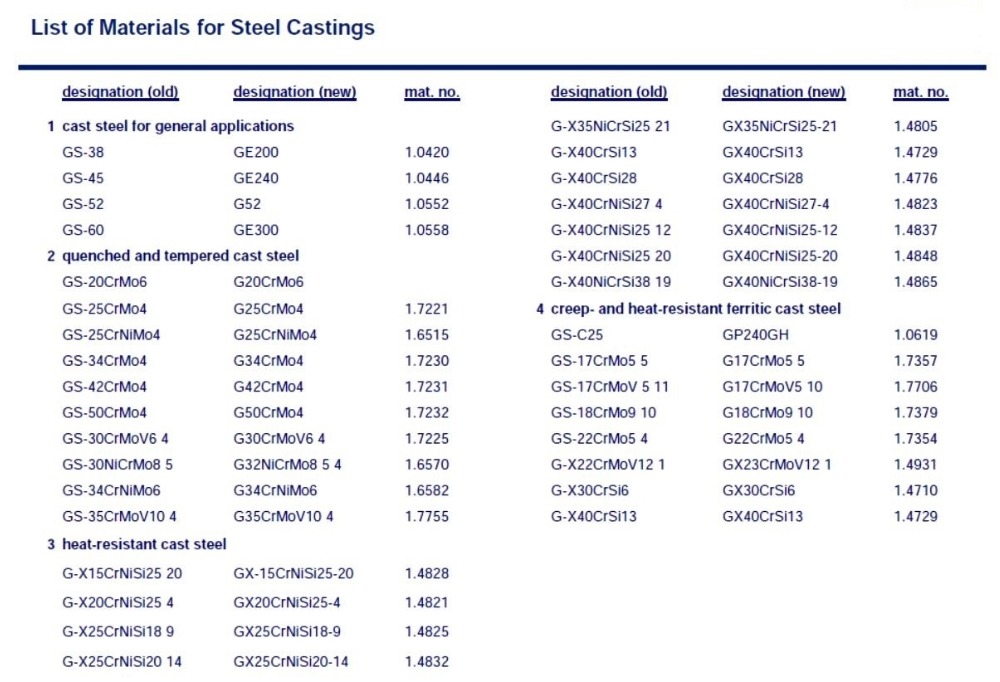

HP Casting Materials are listed but not limited as following

Company ISO Certificates & Patents:

Questionare About Inquiry On Casting Materials

1. The information required

|

1 |

Company Contact Info |

|

|

2 |

number of wear parts per set [pieces] |

|

|

3 |

weight of wear part [kg] |

|

|

4 |

material to be crushed |

|

|

5 |

current wear part material |

|

|

6 |

current life time of the wear part [h or t with t/h] |

|

2. Additional information of the crusher (if available)

|

1 |

type of crusher / manufacturer |

|

|

2 |

number of rotors [pieces] |

|

|

3 |

diameter of the rotor [mm] |

|

|

4 |

rotational speed of the rotor [r/min] |

|

|

5 |

amount of crushed material [t/h] |

|

|

6 |

working hours of the crusher [h per week] |

|

|

7 |

working temperature [°C] |

|

3. Additional information of the material to be crushed (if available)

|

1 |

grain size before crushing [cm] |

|

|

2 |

grain size after crushing [cm] |

|

|

3 |

characteristic features of the material (hardness, corrosive, abrasive) |

|

4. Remarks